But over the years several manufacturers have developed variable speed electronically commutated motors ecms specifically designed as retrofit replacements for faulty psc motors.

Variable speed furnace fan retrofit.

When the r g circuit is made the blower motor operates on heating speed.

The higher the seer the lower your utility bills.

The term variable speed furnace is used to describe furnaces that have a variable speed blower motor.

In addition to better energy efficiency and temperature control variable speed furnaces deliver better indoor air quality as a result of varying blower motor speed.

These blower motors are the motors that move air through the ductwork in your home.

While not all contractors consistently offer ecms those who do often report increased profits as well as improved customer comfort and satisfaction.

Since 1985 furnace manufacturers have used higher efficiency variable speed bpm fan motors also known as electronically commutated motors or ecms in some high end residential furnaces.

The control module only uses two speeds one for cool and one for heat fan.

Running the heating system s fan continuously allows the furnace s blower motor to continue air circulation even when heating is not required.

This is not new technology said christopher mohalley master ecm trainer at regal beloit.

Furnaces without variable speed technology use a simple motor with multiple speed settings.

There are many reasons for choosing a variable speed furnace but the main reason is comfort.

For refrigeration evaporator fan motors.

The term variable speed refers to the furnace s fan motor which moves at different speeds to precisely control the flow of heated and cooled air throughout your home.

Either replace the furnace with one equipped with a variable speed blower or stick with single stage equipment.

Carrier gas furnaces with greenspeed intelligence monitor temperature and humidity inside and out then automatically vary furnace operation as needed to provide an ideal combination of comfort and energy efficiency.

Better airflow control means a better balance of temperature and humidity.

The problem is the furnace control module doesn t use a separate speed when the unit is running in continuous fan mode.

During the cooling mode variable speed systems typically result in an efficiency gain of about 1 seer seasonal energy efficiency ratio.

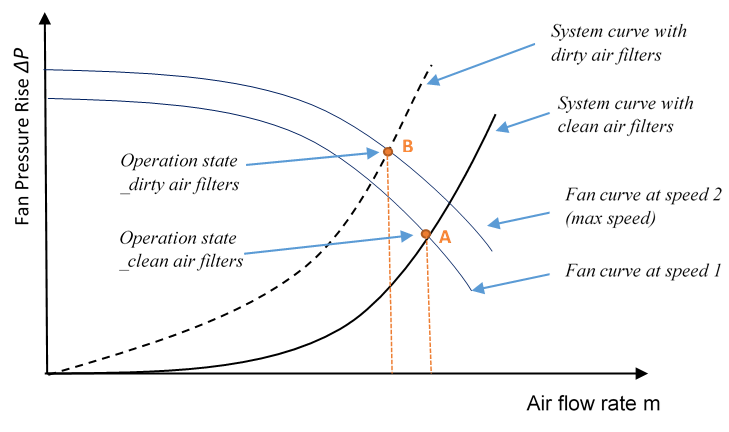

A temperature based variable speed fan control may cause problems especially during defrost cycles.

In recent years new furnaces with bpm motors have gained market share.

Temperature rise declines as the outdoor temperature drops.

These speeds are used by a contractor to adjust airflow to the proper amount.

If a variable speed control is used it may attempt to compensate by reducing airflow across the indoor coil resulting in lower efficiency and capacity.