It s a part of the jayco difference.

Vaccuum laminated walls in rv s.

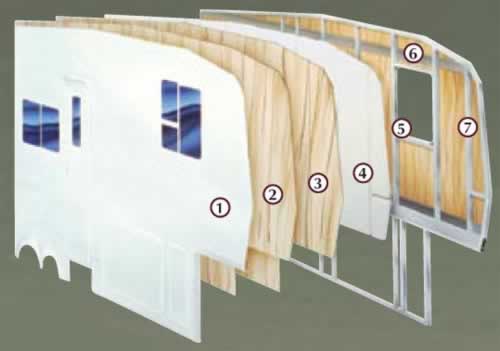

They are produced using a patented blend of polypropylene and fiberglass to create a strong lightweight quiet weather and temperature resistant odorless and environmentally friendly wall that will increase the life of your rv.

The walls are installed to the roof and floor substrate using various techniques to add strength and durability to the unit.

Compositek construction results in a stronger stiffer trailer with the durability and weight distribution only found in monocoque aeronautical engineering.

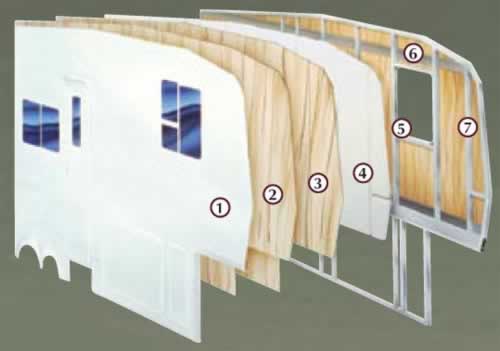

Stronghold vbl aluminum framed vacuum bond lamination.

The exterior finish can be also color toned on some of the higher end trailers and motorhomes.

The wall is layered with glue in between the layers and then the whole wall is vacuum compressed to apply force to ensure good bonding of the glue.

Every sidewall rear wall and slide room wall is bonded together for a minimum of 16 minutes under 144 tons of pressure to create the lightest yet strongest construction available in the rv industry.

Layer one is the inside wall complete with wall covering.

Well the name pretty much explains it.

It creates a wall roof or floor that is stronger than normal construction process.