These planks or sheets are then used for a variety of purposes including making furniture stout flooring and this type of wood is often used in truck beds and vans as well.

Technology student laminating wood.

It is light brown in colour and more difficult to use compared to pine.

Students to investigate adhesives.

Here is an easy trick to glue laminate wood evenly with minimal sanding.

Pine is a relatively cheap wood used in the building trade and for furniture.

Commercial lamination takes two forms.

It is positioned on the edge of the manmade board natural wood side facing upwards.

Students to create a wood laminated wooden chip fork.

It is pale in colour quite easy to cut and shape and machines relatively well.

Cold lamination and hot lamination.

To get started cut three pieces of 3 mm thick wood.

Examples of a hardwoods.

A strip of veneer is cut slightly longer than the edge of the board.

Plywood or aeroply will give you the best results but you can also soak or steam your wood to make it more flexible if needed.

Complex shapes can be achieved with one piece of laminated material.

These processes are ideal for printed posters that need an additional layer of protection.

One side is natural wood and the other is a layer of glue adhesive.

Both processes are similar as they utilise rollers pressing a layer of polyethylene against a printed surface.

Students to create a fact file on wood lamination joining methods for plastics metals and adhesives.

Students to investigate joining methods for plastics and metals.

The natural wood gives the ideal finish to furniture such as chairs.

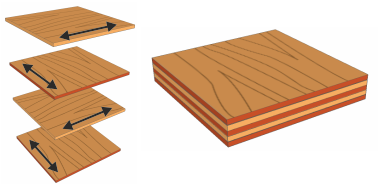

When thin layers of veneer are glued together forming one part they are called laminates.

Max thickness of laminates veneers is 3mm.

The steel chromed legs give the chair a contemporary look.

This warms and melts the glue.

Many layers of wood are bonded together and the layers are then cut into either planks or sheets.

The natural wood gives a quality finish.

Mahogany is quite expensive and is used for good quality furniture and hardwood windows.

Laminated wood is suitable because it can be formed into relatively complex shapes and forms.

A hot iron is placed on top of the veneer.

Complex shapes can even be achieved with one piece of laminated material.